Release Notes 1.15.0 - Durst Workflow

Innovations in Version 1.15.0

With version 1.15.0, users can take advantage of several innovations in the environment of Cutter Devices, Verification and Imposition of Print Data. In addition, improvements have been made in Data Preparation and Data Verification, and further translations were carried out.

Features

VDP Editor Features

VDP Editor Features

A browser-based VDP Editor for creating and managing variable data is available in the Work- flow. The following new features and improve- ments have been implemented:

Variable images – From now on, all sup- ported file formats are generated in real time and also displayed in the VDP Editor.

Magnetic guides – Objects as well as guides behave magnetically. This allows you to quickly align guides to existing objects as well as objects to guides.

Close VDP- Editor – As part of this release, a save function has been added to the close function.

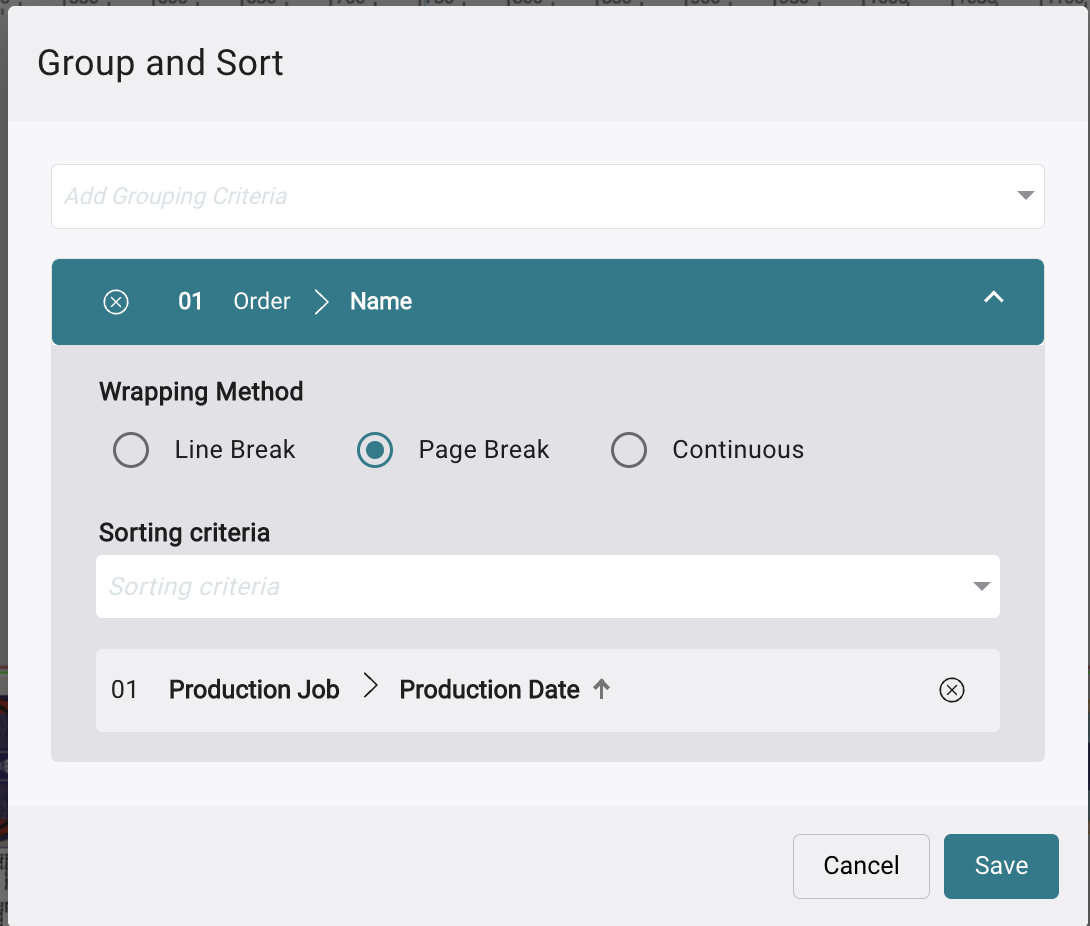

Grouping and sorting

In this version, a new method for grouping placed items has been implemented. Sorting and pagi- nation criteria can be applied within these groups.

Step & Repeat extension

Starting from this version, items of different sizes can be imposed in the “Step & Repeat” mode.

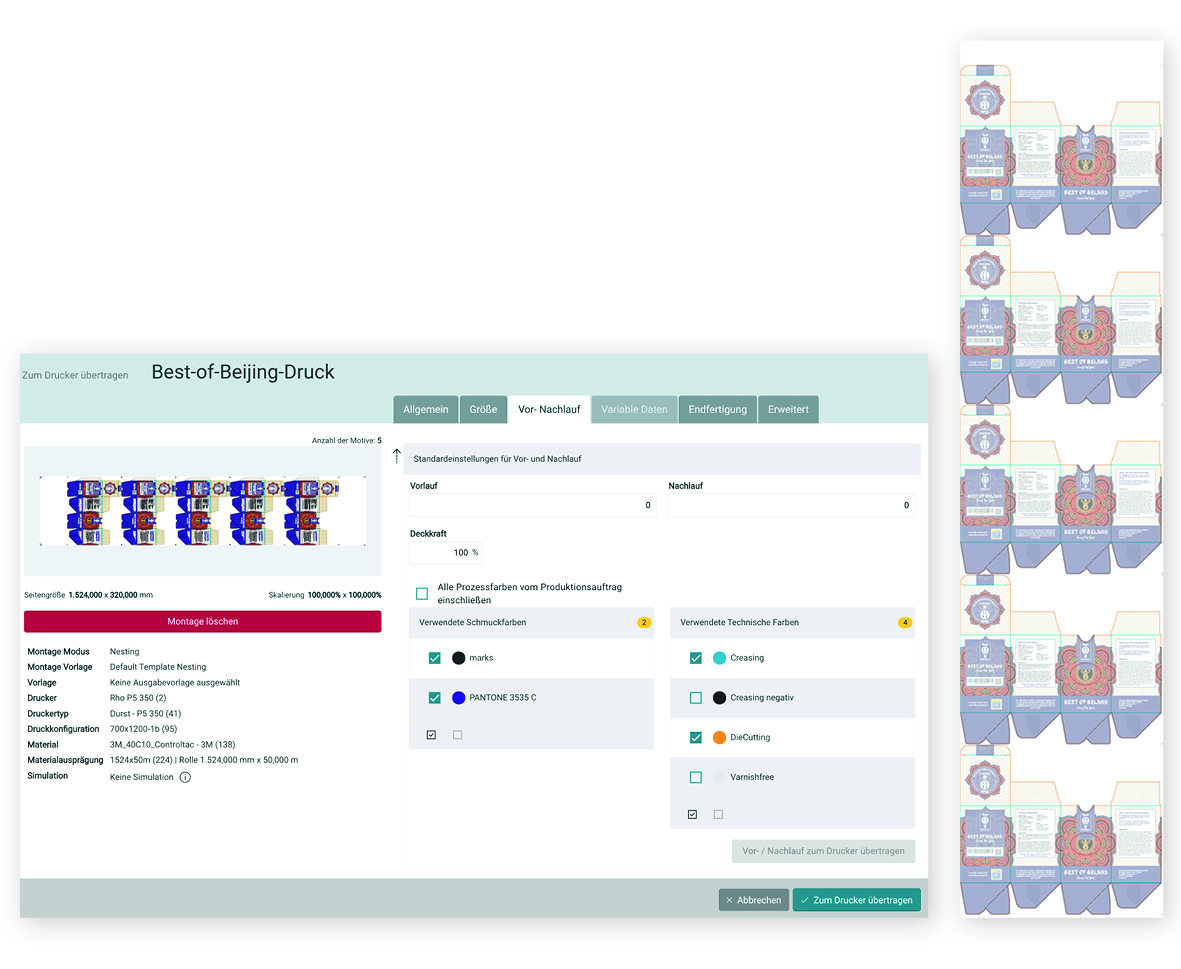

Lead-in and Lead-out

For the item to be printed, the opacity for lead-in and lead-out can be determined. The

opacity regulation only affects the printitem, all included technical colors areprinted with 100%.

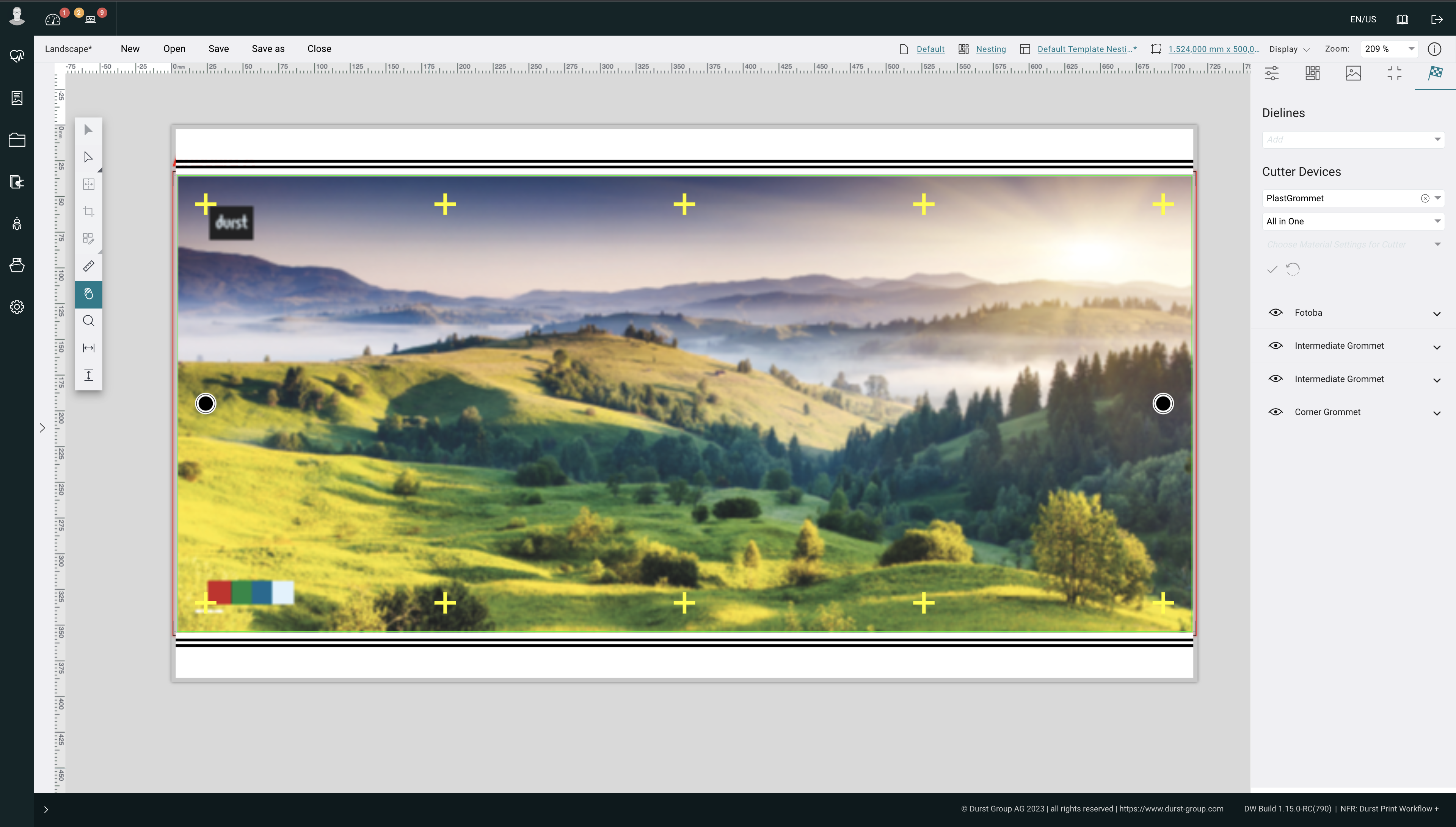

Plast Grommet – All in one

The „All in One“ cutting or eyelet finishing ma- chine from PlastGrommet has been integrated into the Workflow. All specially required eyelets and cutting marks are included in the assembly editor.

»White« handling for output devices

If there is no white ink in the output device, all ar- eas - in a print item - which contain the spot color »white« are converted to CMYK 0/0/0/0. A system setting is available for this.

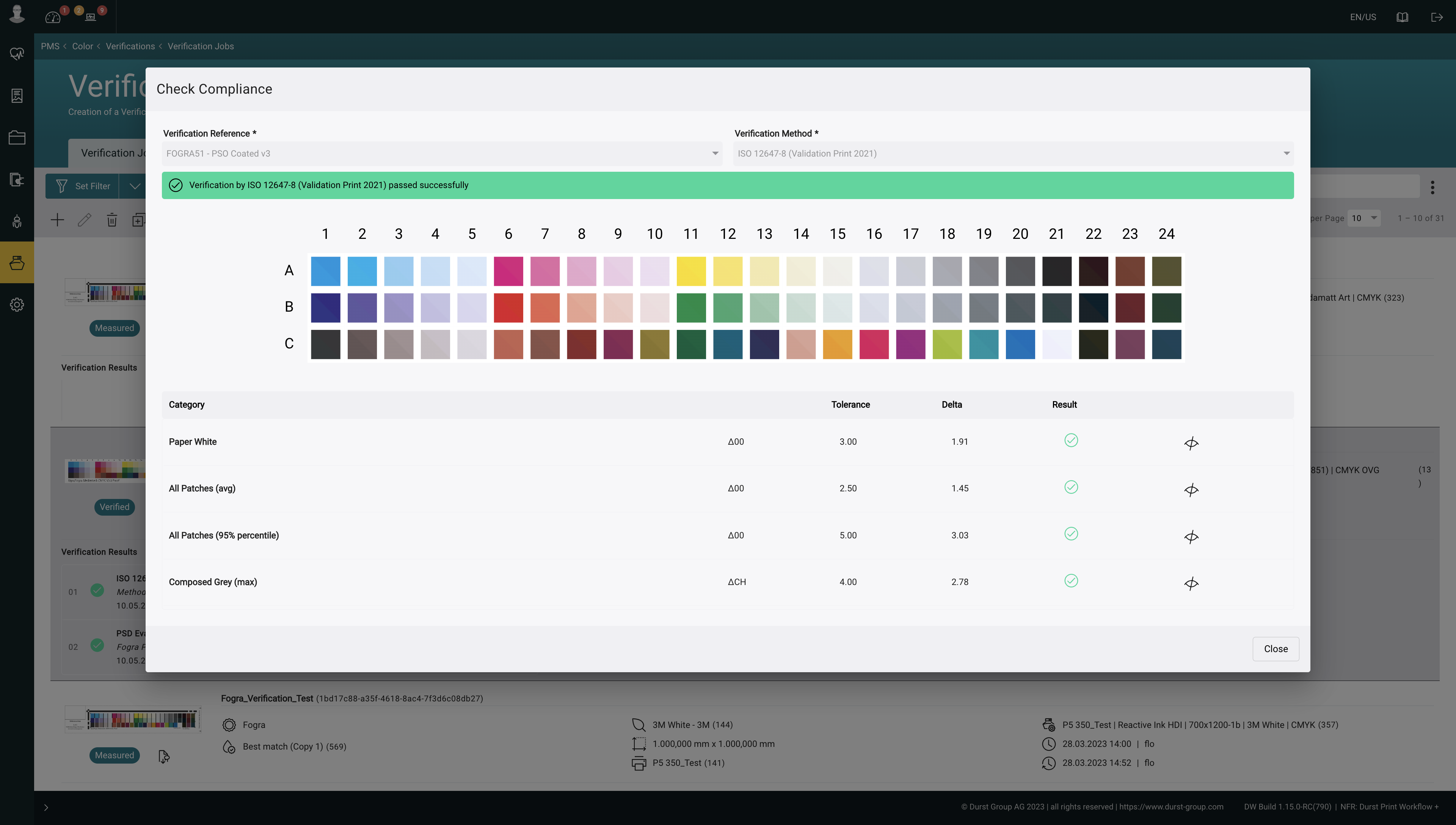

Verification

Verification

From this version on, it is possible to verify a color strategy against the FOGRA and G7 standards. Furthermore, comparative measurements re- garding stability between printing systems as well as production run can be made.

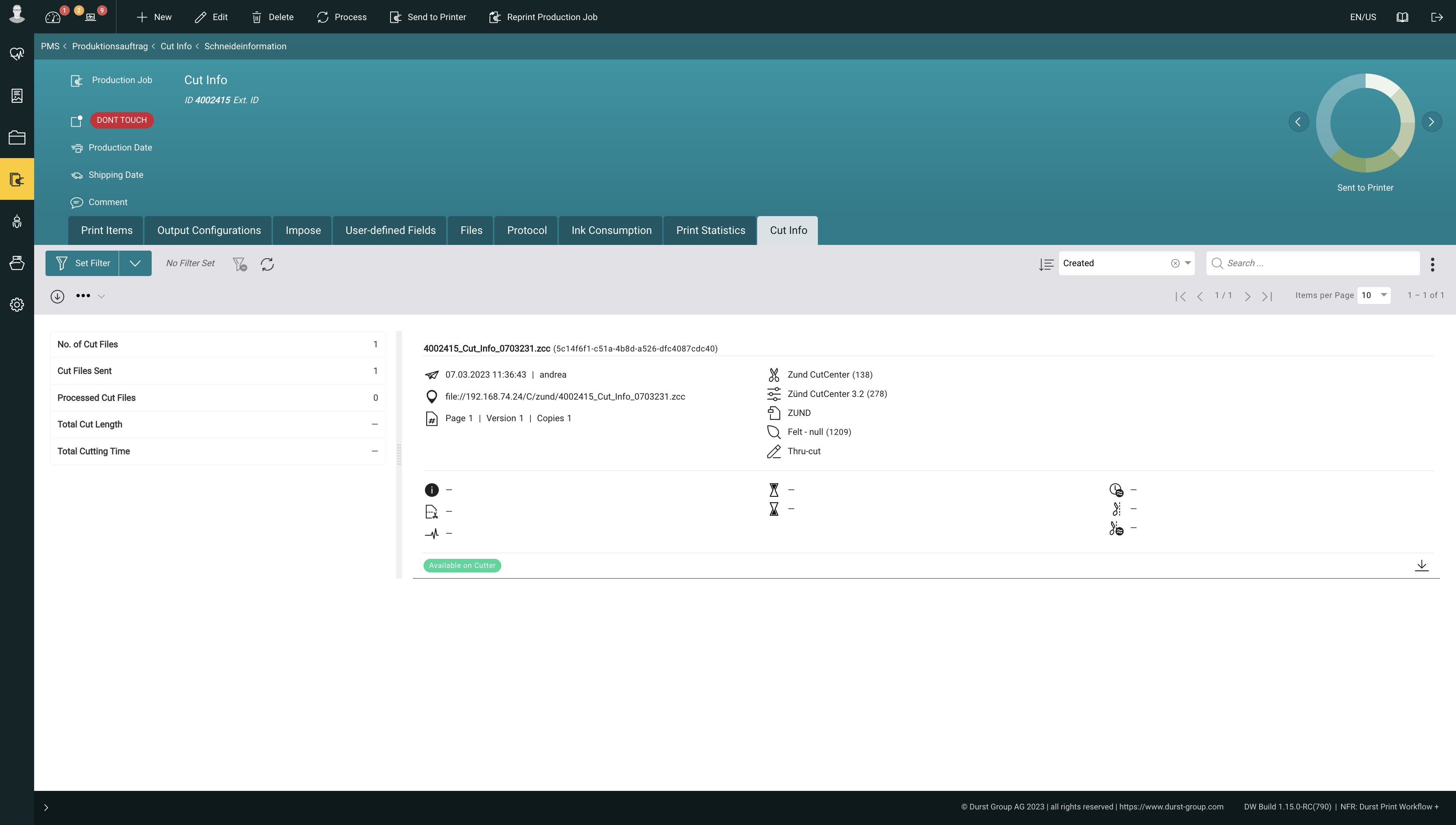

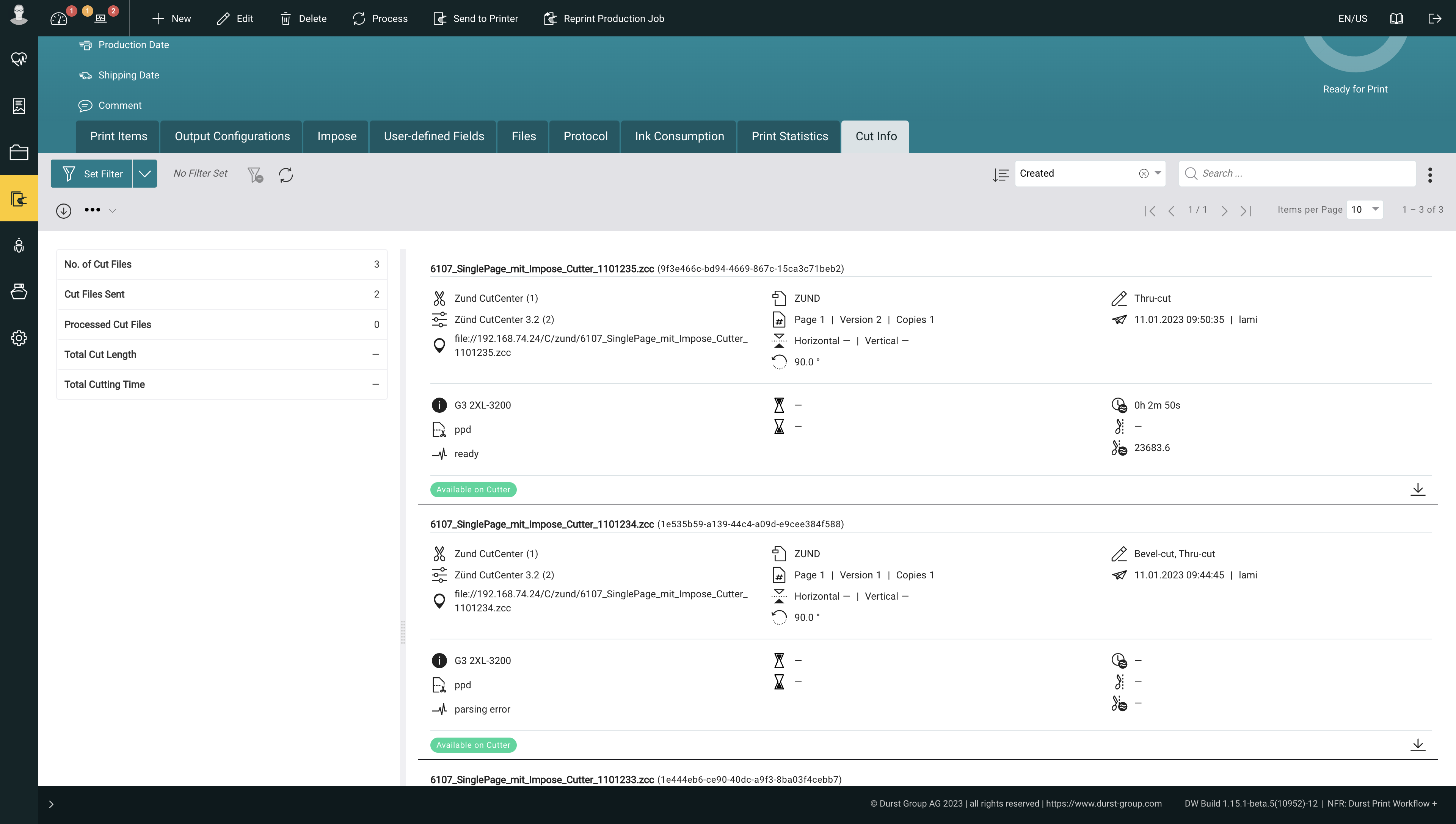

Cut information per production job

In the new tab „Cut info“ cutting data of the production job are stored or displayed. Each created cut-file is listed with some additional information.

Improvements

Bidirectional integration for cutter devices

Bidirectional integration for cutter devices

Individual cutter devices can send information back to the Workflow, which is then subsequent- ly displayed in the „Cut info“ tab. Currently, this bidirectional integration is possible with Zünd cutter devices and the OptiScout cutter software.

Contour Nesting

With this version, improvements in performance and speed have been carried out.

XML hotfolder

XML hotfolder

Starting from this version, fixup chains can be defined in the hotfolder XML file.

Check-in and correction templates

Check-in and correction templates

The creation and saving of Check-in Preflight and Fixup Templates has been revised and extended. It is now possible to save Fixups and Checks in a user-defined Check-in Profile.

for Workflow +

for Workflow + * for Workflow + with Additional Package

* for Workflow + with Additional Package * for Workflow with Additional Package

* for Workflow with Additional Package